Been seeing these pop up on a couple different sites for Forced Induction applications.

Basic idea is that they provide balanced cylinder filling, but for the K-series they would serve double duty by allowing us to run the throttle body facing the opposite direction, ideal for charge pipe routing.

Taken from http://www.bufkinengineering.com/

1985 Pike's Peak cars and Audi Group B S1 Evo 2 had these versions fitted:

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

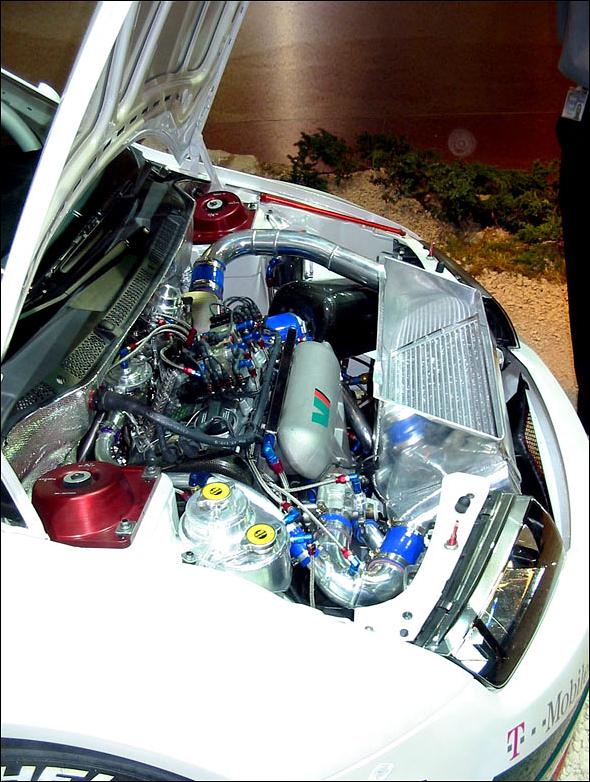

Audi R8 Le Mans car

![Image]()

Manifolds made by Lehmann Motoren in Liechtenstein

![Image]()

![Image]()

![Image]()

Another example

![Image]()

Basic idea is that they provide balanced cylinder filling, but for the K-series they would serve double duty by allowing us to run the throttle body facing the opposite direction, ideal for charge pipe routing.

Taken from http://www.bufkinengineering.com/

Ok, basic idea sounds good. Now some pics.

1985 Pike's Peak cars and Audi Group B S1 Evo 2 had these versions fitted:

Audi R8 Le Mans car

Manifolds made by Lehmann Motoren in Liechtenstein

Another example