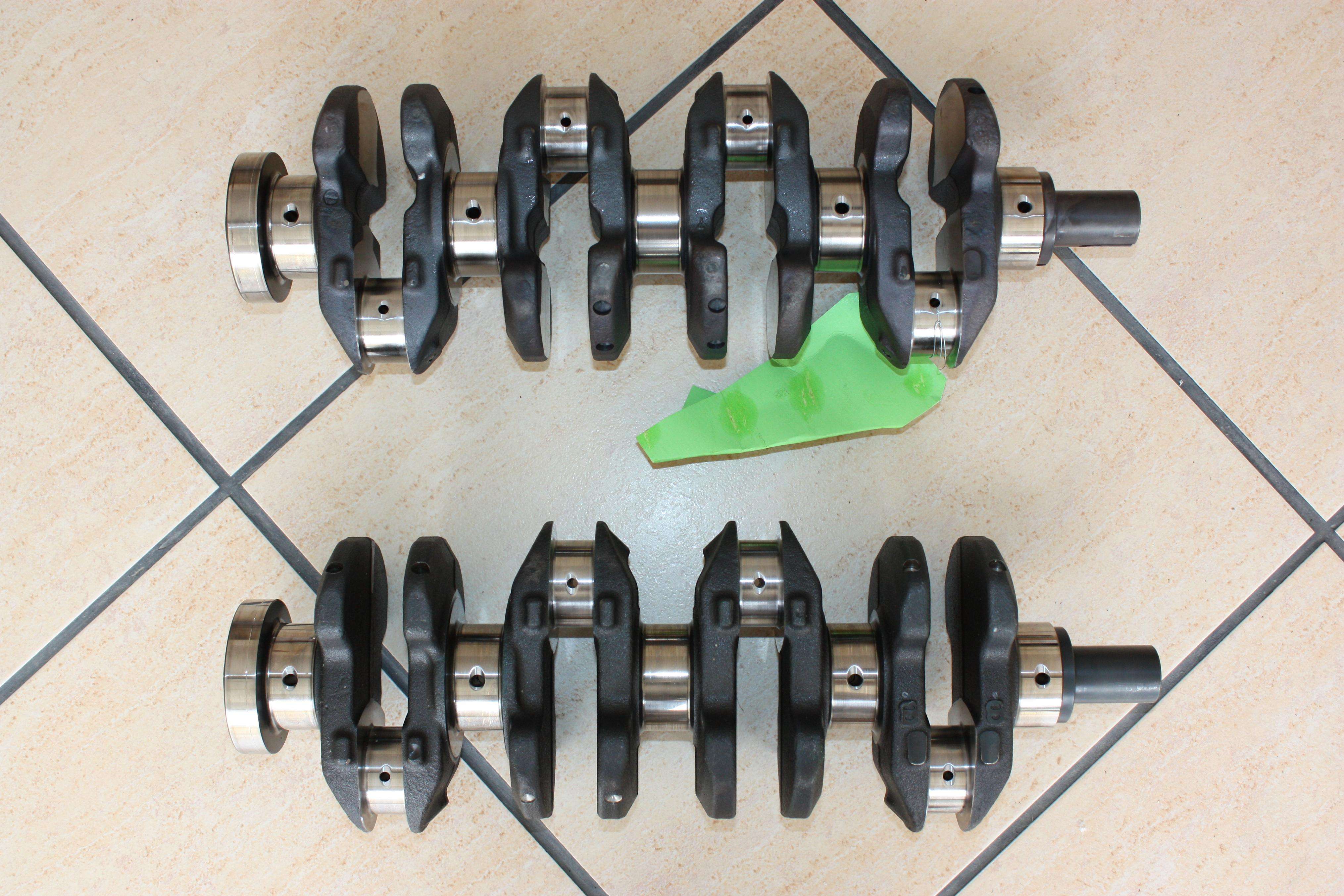

I'm just wondering if there are any differences between the TSX crank and the Accord cranks in the K24s. There is a huge price difference between the two and I need a K24 crank for a stroker motor that I'm building for an S2000.

Obviously, I know the stroke is the same for both but I'm curious if the TSX one is more balanced or something? It's much more expensive than the Accord one. Or maybe it's just part inflation based off of brand?

If anyone has any information on this it would be greatly appreciated.

Obviously, I know the stroke is the same for both but I'm curious if the TSX one is more balanced or something? It's much more expensive than the Accord one. Or maybe it's just part inflation based off of brand?

If anyone has any information on this it would be greatly appreciated.