I thought i would start a new thread for searching purposes and for any future builds out there.

This is my build thread with the k24a2 head http://www.k20a.org/forum/showthread.php?t=75424

Well after the setup was dyno tuned it became apparent that something was not right as the motor was not putting down the expected power and the vtc was all over the board and wanting 40deg. Vtc all the way to redline. Which is how this thread started http://www.k20a.org/forum/showthread.php?t=77640. After some trouble shooting and coming up empty handed. There was only one thing left to do. Swap the head!

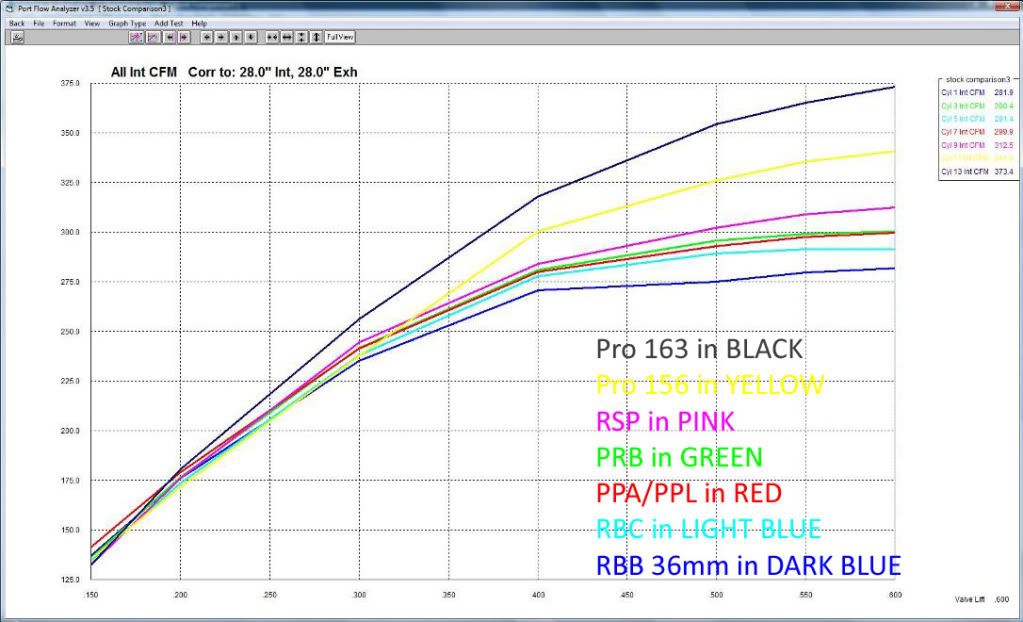

I was able to pickup an rsp head from morgan at synapseturbo.com. Threw in some supertech valves as the head was new and i didnt want to use the orginal tsx valves that came in the longblock.

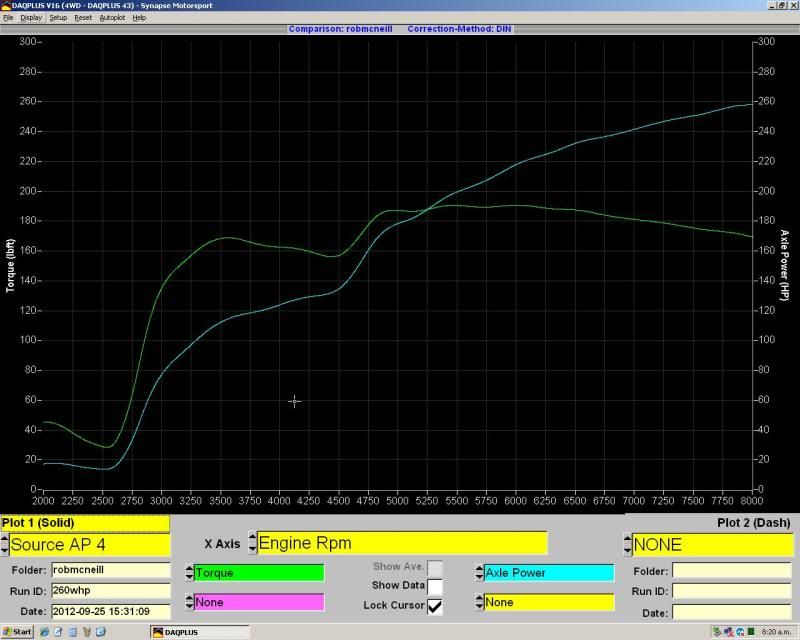

Well i installed it last week and morgan was able to get me in for a retune. Needless to say i very happy with the out come. The motor picked up 20+hp and is ready to be pushed further as my rev limit is only set to 8000. I plan to swap out some minor bolt ons and tune on e85 as i am running 93 oct.

Here is the motor with k24a2 head

![Image]()

This is my build thread with the k24a2 head http://www.k20a.org/forum/showthread.php?t=75424

Well after the setup was dyno tuned it became apparent that something was not right as the motor was not putting down the expected power and the vtc was all over the board and wanting 40deg. Vtc all the way to redline. Which is how this thread started http://www.k20a.org/forum/showthread.php?t=77640. After some trouble shooting and coming up empty handed. There was only one thing left to do. Swap the head!

I was able to pickup an rsp head from morgan at synapseturbo.com. Threw in some supertech valves as the head was new and i didnt want to use the orginal tsx valves that came in the longblock.

Well i installed it last week and morgan was able to get me in for a retune. Needless to say i very happy with the out come. The motor picked up 20+hp and is ready to be pushed further as my rev limit is only set to 8000. I plan to swap out some minor bolt ons and tune on e85 as i am running 93 oct.

Here is the motor with k24a2 head