K20 Rotrex/sequential/dry sump'd Pug 106

Hello guys, I've started my k20 pug 106 project now. In the next few months things should start to shape up nicely.

The main goal of my car is to make it as fast as possible for the money I have. There are no restrictions like there would be in some race series cars.

The general goal is to get the weight down to around 800kgs (roughly 1750lbs) and for the engine to produce around 450hp.

This project is by no means all about power, there will be a proper roll cage installed, digital dash, widetrack suspension, remote reservoir dampers and some nice brakes.

Here are a few taster pictures for now while I get some proper progress together..

Here's how it started

![Image]()

![Image]()

Designed and machined my own mounts (k-swap mounts would hit my chassis)

![Image]()

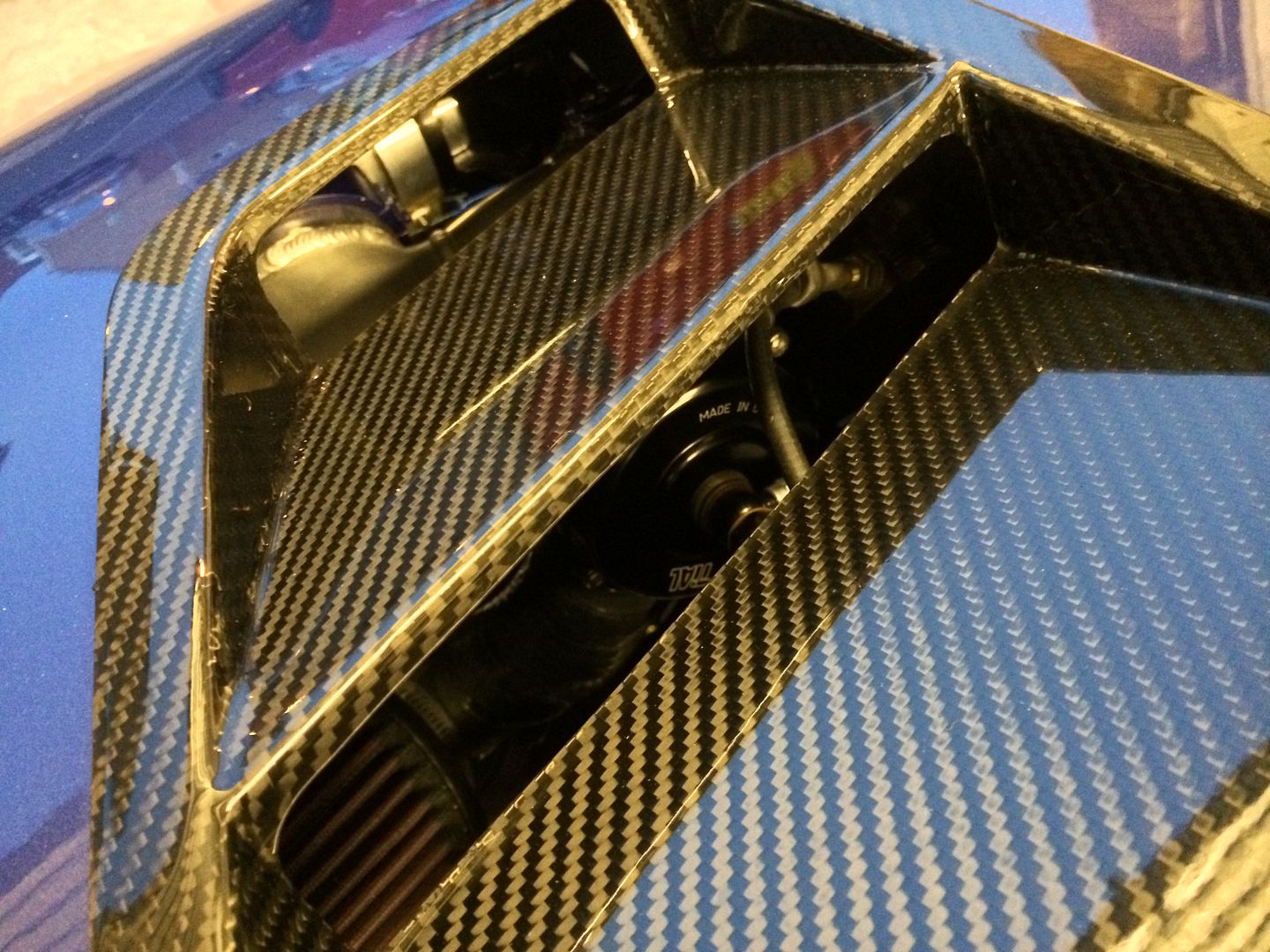

Add this into the mix and things get interesting

![Image]()

![Image]()

Add these things get more interesting

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

Lots more things happening including tilton pedal box and chassis work.

I'll keep it updated, this will be pretty nasty

Hello guys, I've started my k20 pug 106 project now. In the next few months things should start to shape up nicely.

The main goal of my car is to make it as fast as possible for the money I have. There are no restrictions like there would be in some race series cars.

The general goal is to get the weight down to around 800kgs (roughly 1750lbs) and for the engine to produce around 450hp.

This project is by no means all about power, there will be a proper roll cage installed, digital dash, widetrack suspension, remote reservoir dampers and some nice brakes.

Here are a few taster pictures for now while I get some proper progress together..

Here's how it started

Designed and machined my own mounts (k-swap mounts would hit my chassis)

Add this into the mix and things get interesting

Add these things get more interesting

Lots more things happening including tilton pedal box and chassis work.

I'll keep it updated, this will be pretty nasty