Re: Fuel Tech Section

I was going to add more to this segment before dropping it here, but I think that this will suffice for now. I would like to find some pictures online of different flame fronts after ignition so that detonation and burn can both be better described.

Some good definitions for future use...

http://www.eng-tips.com/viewthread.cfm?qid=34183&page=33

Glossary on Explosion Dynamics

Some of the language used to describe explosions is very precise and scientific; other terms, including the very nature of an explosion itself, are quite ambiguous. The following list of terms is not intended to be exhaustive but simply to provide an explanation for some of the most commonly used concepts.

Blast or Blast Wave This is the rapid change in air pressure that propagates away from the region of an explosion. A sharp jump in pressure is known as a shock wave and a slow rise is known as a compression wave. Weak pressure waves propagate with the speed of sound and shock waves always travel supersonically, faster than the speed of sound. A blast wave is produced by an explosion because the explosive event displaces the surrounding air rapidly.

Burning speed This is the speed with which a smooth (laminar) flame advances into a stationary mixture of reactants. Burning speeds in hydrocarbon fuels mixed with air are typically less than 0.5 m/s. The burning speed is a function of the concentration of the fuel, temperature, and pressure of the mixture.

Deflagration This is a propagating flame that moves subsonically (the flame speed is less than the speed of sound) in a mixture of fuel and oxidizer.

Deflagration to Detonation Transition (DDT) In certain circumstances, a flame may accelerate to high velocities (greater than 1000 m/s) and suddenly become a detonation instead of a deflagration. The circumstances involve a sufficiently sensitive mixture (very rapid chemical reaction) in a geometrical configuration that is favorable to flame acceleration - this usually requires confinement and obstructions or obstacles in the path of the flame. Such mixtures are characterized by a small detonation cell width, high flame speed, and high volume expansion ratio.

Detonation This is a supersonic combustion wave. Detonations in gases propagate with velocities that range from 5 to 7 times the speed of sound in the reactants. For hydrocarbon fuels in air, the detonation velocity can be up to 1800 m/s. The ideal detonation speed, known as the Chapman-Jouguet velocity, is a function of the reactant composition, initial temperature and pressure.

Detonation cell width This is the characteristic width of the cellular pattern that is created by the instabilities that plague all propagating gaseous detonation waves. The cell width is measured by a sooted sheet or foil of metal inserted inside a tube used for detonation experiments. Detonation cell widths are used to characterize the sensitivity or susceptibility of a mixture to detonation. Sensitive mixtures (acetylene-oxygen) have cell sizes less than 1 mm; insensitive mixtures (methane-air or any lean hydrocarbon-air mixture) can have cell sizes of up to 1 m.

Explosion There is no fixed definition of an explosion. Events that are described as explosions include a rupturing water boiler, a flash of light created by an electrical short circuit, detonation of a high explosive, deflagration of a tank containing an explosive fuel-air mixture, or the shock wave, fireball, and debris cloud produced by a thermonuclear detonation. The AIChE suggests that an explosion is "A release of energy that causes a blast". Perhaps the best definition was given by Joseph Needham, "An explosion may be defined as a loud noise accompanied by the sudden going away of things from the places where they were before." - see p. 110 of The Gunpowder Epic, Vol 5, Part 7, Science and Civilization in China.

Fire This is a flame that is produced over a stationary fuel source such as a liquid hydrocarbon pool or solid such as wood.

Flame This is a thin zone of combustion in which diffusion plays a dominant role. Flames in hydrocarbon fuels and air are less than 0.1 mm thick for stoichiometric mixtures.

Flame speed This is the speed with which a flame, possibly turbulent, appears to move relative to a stationary observer. The flame speed can be much larger than the burning velocity due to expansion of the combustion products, instability, and turbulent deformation of the flame. Flame speeds of 10-100 m/s are commonly observed for hydrocarbon-air mixtures and it is possible under exceptional circumstances to have speeds up to 1000 m/s.

Flammability A fuel-air mixture is flammable when combustion can be started by an ignition source. The main fact is the proportions or composition of the fuel-air mixture. A mixture that has less than a critical amount of fuel, known as the Lean Flammability Limit (LFL), or greater than a critical amount of fuel, known as the rich or Upper Flammability Limit (UFL), will not be flammable. For example, the lean flammability limit for Jet A (aviation kerosene) in air at sea level is a concentration (by volume or partial pressure) of about 0.7%. The rich flammability limit is about 4.8% by volume or partial pressure. Flammability limits are not absolute, but depend on the type and strength of the ignition source. Previous studies on flammability limits of hydrocarbon fuels have shown that the stronger the source of the ignition stimulus, the leaner the mixture that can be ignited. Flammability limits also depend on the type of atmosphere (for example, limits are much wider in oxygen than in air), the pressure, and the temperature of atmosphere.

Flash point This is the minimum temperature at which the vapor above a liquid fuel will first support a combustion transient or "flash". The flash point is measured by a standardized test using a small quantity (50 cc) of liquid that is slowly heated (about 1 deg C/minute) until a flash is observed when an open flame is dipped down into a covered vapor space. The legal description of flammable is used for all liquids with a flash point less than 100 deg C, and the term combustible is used for liquids with a flash point in excess of 100 deg C.

Fuel-air mass ratio This is the ratio of the mass of fuel to the mass of air in the reactants. The fuel-air ratio is a method of measuring the composition of a potentially flammable mixture.

Lean mixture This is a mixture containing less than the stoichiometric amount of fuel. Combustion of a lean mixture will result in excess oxidizer remaining in the products.

Minimum Ignition Energy This is the lowest possible energy that will result in the ignition of a flammable mixture by an electrical discharge. The minimum ignition energy depends on the composition of the mixture and can be as low as 200 microJoules for many common hydrocarbon fuels.

Overpressure This is the pressure in excess of the ambient value that is created by the explosion process. The peak overpressures associated with deflagrations inside closed vessels can be as high as 10 times the initial pressure.

Partial pressure This is the pressure created by one component of gas mixture. The partial pressure of fuel vapor in a well-mixed ullage over a liquid fuel layer is equal to the vapor pressure of the liquid under those conditions. Strictly speaking, this is the case only for a single component fuel (such as hexane) but is also valid for multicomponent fuels like kerosene as long as sufficient liquid is present.

Pool Fire This is a flame over a puddle or pool of liquid fuel. The heat released by the combustion of the vapor fuel supplies the energy to vaporize the liquid.

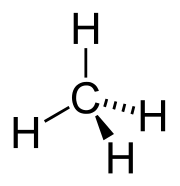

Reactants This is the mixture of Fuel and Oxidizer molecules that are burned in the combustion process.

Rich mixture This is a mixture containing more than the stoichiometric amount of fuel. Combustion of a rich mixture will result in excess decomposed fuel (hydrogen and carbon monoxide for hydrocarbon fuels) remaining in the products.

Stoichiometric ratio The proportions of fuel and oxidizer that will result in optimal combustion are known as a stoichiometric ratio. The optimal ratio is determined by finding the amount of air that will result in the products of the combustion reaction containing only water and carbon dioxide with no left over oxygen. A stoichiometric mixture of Jet A and air contains about 1.2% fuel by volume or partial pressure.

Ullage This is the volume in a liquid fuel tank that is not occupied by liquid fuel. This is sometimes referred to as the vapor space since it is filled with a mixture of fuel vapor and a cover gas, air in the case of commercial airplanes.

I was going to add more to this segment before dropping it here, but I think that this will suffice for now. I would like to find some pictures online of different flame fronts after ignition so that detonation and burn can both be better described.

Some good definitions for future use...

http://www.eng-tips.com/viewthread.cfm?qid=34183&page=33

Glossary on Explosion Dynamics

Some of the language used to describe explosions is very precise and scientific; other terms, including the very nature of an explosion itself, are quite ambiguous. The following list of terms is not intended to be exhaustive but simply to provide an explanation for some of the most commonly used concepts.

Blast or Blast Wave This is the rapid change in air pressure that propagates away from the region of an explosion. A sharp jump in pressure is known as a shock wave and a slow rise is known as a compression wave. Weak pressure waves propagate with the speed of sound and shock waves always travel supersonically, faster than the speed of sound. A blast wave is produced by an explosion because the explosive event displaces the surrounding air rapidly.

Burning speed This is the speed with which a smooth (laminar) flame advances into a stationary mixture of reactants. Burning speeds in hydrocarbon fuels mixed with air are typically less than 0.5 m/s. The burning speed is a function of the concentration of the fuel, temperature, and pressure of the mixture.

Deflagration This is a propagating flame that moves subsonically (the flame speed is less than the speed of sound) in a mixture of fuel and oxidizer.

Deflagration to Detonation Transition (DDT) In certain circumstances, a flame may accelerate to high velocities (greater than 1000 m/s) and suddenly become a detonation instead of a deflagration. The circumstances involve a sufficiently sensitive mixture (very rapid chemical reaction) in a geometrical configuration that is favorable to flame acceleration - this usually requires confinement and obstructions or obstacles in the path of the flame. Such mixtures are characterized by a small detonation cell width, high flame speed, and high volume expansion ratio.

Detonation This is a supersonic combustion wave. Detonations in gases propagate with velocities that range from 5 to 7 times the speed of sound in the reactants. For hydrocarbon fuels in air, the detonation velocity can be up to 1800 m/s. The ideal detonation speed, known as the Chapman-Jouguet velocity, is a function of the reactant composition, initial temperature and pressure.

Detonation cell width This is the characteristic width of the cellular pattern that is created by the instabilities that plague all propagating gaseous detonation waves. The cell width is measured by a sooted sheet or foil of metal inserted inside a tube used for detonation experiments. Detonation cell widths are used to characterize the sensitivity or susceptibility of a mixture to detonation. Sensitive mixtures (acetylene-oxygen) have cell sizes less than 1 mm; insensitive mixtures (methane-air or any lean hydrocarbon-air mixture) can have cell sizes of up to 1 m.

Explosion There is no fixed definition of an explosion. Events that are described as explosions include a rupturing water boiler, a flash of light created by an electrical short circuit, detonation of a high explosive, deflagration of a tank containing an explosive fuel-air mixture, or the shock wave, fireball, and debris cloud produced by a thermonuclear detonation. The AIChE suggests that an explosion is "A release of energy that causes a blast". Perhaps the best definition was given by Joseph Needham, "An explosion may be defined as a loud noise accompanied by the sudden going away of things from the places where they were before." - see p. 110 of The Gunpowder Epic, Vol 5, Part 7, Science and Civilization in China.

Fire This is a flame that is produced over a stationary fuel source such as a liquid hydrocarbon pool or solid such as wood.

Flame This is a thin zone of combustion in which diffusion plays a dominant role. Flames in hydrocarbon fuels and air are less than 0.1 mm thick for stoichiometric mixtures.

Flame speed This is the speed with which a flame, possibly turbulent, appears to move relative to a stationary observer. The flame speed can be much larger than the burning velocity due to expansion of the combustion products, instability, and turbulent deformation of the flame. Flame speeds of 10-100 m/s are commonly observed for hydrocarbon-air mixtures and it is possible under exceptional circumstances to have speeds up to 1000 m/s.

Flammability A fuel-air mixture is flammable when combustion can be started by an ignition source. The main fact is the proportions or composition of the fuel-air mixture. A mixture that has less than a critical amount of fuel, known as the Lean Flammability Limit (LFL), or greater than a critical amount of fuel, known as the rich or Upper Flammability Limit (UFL), will not be flammable. For example, the lean flammability limit for Jet A (aviation kerosene) in air at sea level is a concentration (by volume or partial pressure) of about 0.7%. The rich flammability limit is about 4.8% by volume or partial pressure. Flammability limits are not absolute, but depend on the type and strength of the ignition source. Previous studies on flammability limits of hydrocarbon fuels have shown that the stronger the source of the ignition stimulus, the leaner the mixture that can be ignited. Flammability limits also depend on the type of atmosphere (for example, limits are much wider in oxygen than in air), the pressure, and the temperature of atmosphere.

Flash point This is the minimum temperature at which the vapor above a liquid fuel will first support a combustion transient or "flash". The flash point is measured by a standardized test using a small quantity (50 cc) of liquid that is slowly heated (about 1 deg C/minute) until a flash is observed when an open flame is dipped down into a covered vapor space. The legal description of flammable is used for all liquids with a flash point less than 100 deg C, and the term combustible is used for liquids with a flash point in excess of 100 deg C.

Fuel-air mass ratio This is the ratio of the mass of fuel to the mass of air in the reactants. The fuel-air ratio is a method of measuring the composition of a potentially flammable mixture.

Lean mixture This is a mixture containing less than the stoichiometric amount of fuel. Combustion of a lean mixture will result in excess oxidizer remaining in the products.

Minimum Ignition Energy This is the lowest possible energy that will result in the ignition of a flammable mixture by an electrical discharge. The minimum ignition energy depends on the composition of the mixture and can be as low as 200 microJoules for many common hydrocarbon fuels.

Overpressure This is the pressure in excess of the ambient value that is created by the explosion process. The peak overpressures associated with deflagrations inside closed vessels can be as high as 10 times the initial pressure.

Partial pressure This is the pressure created by one component of gas mixture. The partial pressure of fuel vapor in a well-mixed ullage over a liquid fuel layer is equal to the vapor pressure of the liquid under those conditions. Strictly speaking, this is the case only for a single component fuel (such as hexane) but is also valid for multicomponent fuels like kerosene as long as sufficient liquid is present.

Pool Fire This is a flame over a puddle or pool of liquid fuel. The heat released by the combustion of the vapor fuel supplies the energy to vaporize the liquid.

Reactants This is the mixture of Fuel and Oxidizer molecules that are burned in the combustion process.

Rich mixture This is a mixture containing more than the stoichiometric amount of fuel. Combustion of a rich mixture will result in excess decomposed fuel (hydrogen and carbon monoxide for hydrocarbon fuels) remaining in the products.

Stoichiometric ratio The proportions of fuel and oxidizer that will result in optimal combustion are known as a stoichiometric ratio. The optimal ratio is determined by finding the amount of air that will result in the products of the combustion reaction containing only water and carbon dioxide with no left over oxygen. A stoichiometric mixture of Jet A and air contains about 1.2% fuel by volume or partial pressure.

Ullage This is the volume in a liquid fuel tank that is not occupied by liquid fuel. This is sometimes referred to as the vapor space since it is filled with a mixture of fuel vapor and a cover gas, air in the case of commercial airplanes.